Causes of Mold in Purple Sand Pots and Solutions to Prevent Mold

![]() Date: Sep 12,2024

Date: Sep 12,2024

Recently, many products that were not prone to mold in the past have also encountered mold problems. Last week, a purple clay pot supplier contacted us to discuss anti-mold solutions at his factory. The company had more than 20,000 sets of purple clay pots stored in its warehouse, but they were found to be moldy before they were shipped.

This not only caused huge economic losses to the company, but also may affect the brand reputation. In order to solve this problem, we analyzed the causes of the mold on the purple clay pots and proposed a subsequent anti-mold solution to ensure that similar problems will not occur again during the storage and transportation of subsequent products.

New purple sand pot is moldy when it leaves the factory , which may be caused by the following reasons:

1. Moisture absorption during production: Purple clay pot is a kind of pottery made of purple clay, which has many tiny pores. These pores easily absorb moisture. During the production process of purple clay pot, especially during the cooling and packaging process after firing, if the humidity is high, this moisture may be retained in the porous structure of the purple clay pot, causing mold growth.

2. Insufficient drying before packaging: After the purple clay pot is produced, if it is packaged directly without sufficient drying, the residual moisture or humidity in the pot cannot evaporate in the sealed packaging, which can easily lead to the growth of mold.

3. Improper storage environment: If the storage environment of the purple clay pot is humid, unventilated, or the temperature is high during storage in the factory, this environment is very conducive to the growth of mold, especially in the case of long-term storage, mold is more likely to grow.

4. Packaging material problem: Using airtight packaging materials, especially in a humid environment, may prevent internal moisture from being discharged, making the purple clay pot more prone to mold during transportation or storage.

5. No sterilization treatment: If the purple clay pots produced in the factory have not undergone effective sterilization or antibacterial treatment, especially if the surface of the pot is not properly cleaned and disinfected before packaging, the residual organic matter and moisture will provide nutrients for mold and cause mold growth.

Precautions:

- Strengthen production environment control: During the production and packaging process, keep the workshop dry and well ventilated, especially before the pot is cooled and packaged, to ensure that there is no residual moisture on the surface of the product.

- Fully dry: Make sure the clay pot is fully dried before packaging, especially in humid seasons or areas with high humidity.

- Use mildew-proof packaging: Use packaging materials with good air permeability. Factories can use iHeir's mildew-proof non-woven bags as mildew-proof protective packaging for casseroles, while also improving the grade of the product.

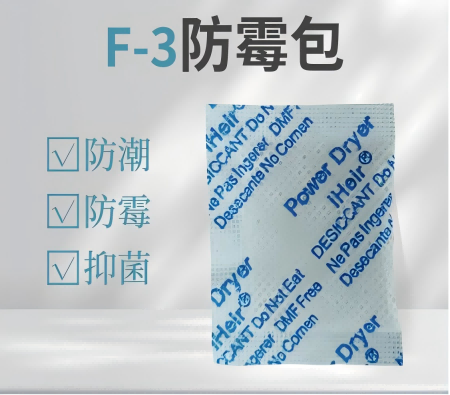

Alternatively, place iHeir-F anti-mold desiccant in the package to prevent moisture from accumulating in the package and kill residual mold spores in the package.