Why Do Mooncake Packaging Boxes Get Moldy? Analysis of the Reasons and Anti-mold Solutions for Mooncake Boxes

![]() Date: Sep 04,2024

Date: Sep 04,2024

Mooncake Box Mold Problem and Anti-Mold Solution

Before the Mid-Autumn Festival, the demand for mooncake boxes surged. However, many factories reported mold problems, leading to potential return risks. iHeir provided a targeted anti-mold solution.

1. Causes of Mold in Mooncake Boxes

1) Material Issues: Paperboard and corrugated board easily absorb moisture, decorative materials are hard to clean, and incompletely dried glue can create damp conditions.

2) Production Process: Glue not fully dried, printing/coating with high moisture, and poor humidity control in workshops can all cause mold growth.

3) Packaging & Storage: If materials absorb moisture before sealing, lack of desiccants, poor barrier packaging, or high warehouse humidity, the risk of mold increases significantly.

2. Anti-Mold Solution

1) Production Stage: Use anti-mold glue such as iHeir-JS Glue Anti-Mold Agent, improve drying processes, and keep workshop humidity under control.

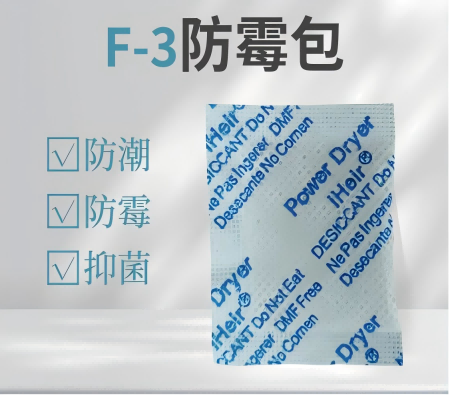

2) Packaging Stage: Place iHeir F Series Power Dryer Desiccant or Power Pak Anti-Mold Chip inside the packaging for moisture absorption and mold prevention.

3) Storage & Transportation: Keep warehouses dry and well-ventilated (≤50% RH) and check regularly to prevent mold spread.

3. Conclusion

By optimizing production processes, using anti-mold additives, and improving packaging and storage methods—together with iHeir-JS Glue Anti-Mold Agent, iHeir F Series Power Dryer, and Power Pak Anti-Mold Chip—moon cake boxes can remain mold-free, ensuring stable quality and protecting brand reputation.