Standard Operating Procedure for Raw Materials (Semi-Finished Products) Warehouse in a Shoe Factory

![]() Date: Aug 31,2024

Date: Aug 31,2024

In the footwear manufacturing industry, the management of raw materials and semi-finished products is crucial. An efficient warehouse management system not only improves production efficiency, but also ensures the quality of the finished products. With the increasing market demand for shoe quality, the Standard Operating Procedures (SOP) for footwear raw materials (semi-finished products) warehouses have become an indispensable part of major shoe factories. Following a scientific operational process for tasks such as material receiving, storage, and delivery can significantly reduce production risks and avoid unnecessary losses.

This article will discuss the standard operational procedures for the raw material (semi-finished products) warehouse of shoes in depth, aiming to assist shoe factories in establishing an efficient warehouse management system. We will analyze various aspects such as the shipment and acceptance of raw materials, warehouse layout and management after receiving goods, control of storage conditions, regular maintenance and cleanliness, as well as inventory management. Practical operational guidelines and precautions will be provided. Through this article, manufacturing companies can optimize warehouse management, enhance production efficiency, and effectively reduce quality issues and cost losses in production.

1. Before shipment: mildew control before fabrics are shipped from leather suppliers

Testing of newly purchased fabrics: Fabrics newly purchased by the factory, especially crazy horse oil leather, color-changing oil leather, oil nubuck leather, suede leather, oil wax leather, woven fabrics and other fabrics with longer fibers and heavier oil content, can be cut in advance and sent to the iHeir laboratory for microbial testing to determine whether mildew treatment is required.

Mildew prevention treatment: The simplest method is to spray iHeir-Spray anti-mold agent on the surface of the leather before packaging it in the leather factory, or put potent anti-mold chips (Power Pak) in the package and seal it (either of these two methods is fine).

2. Inspection before storage

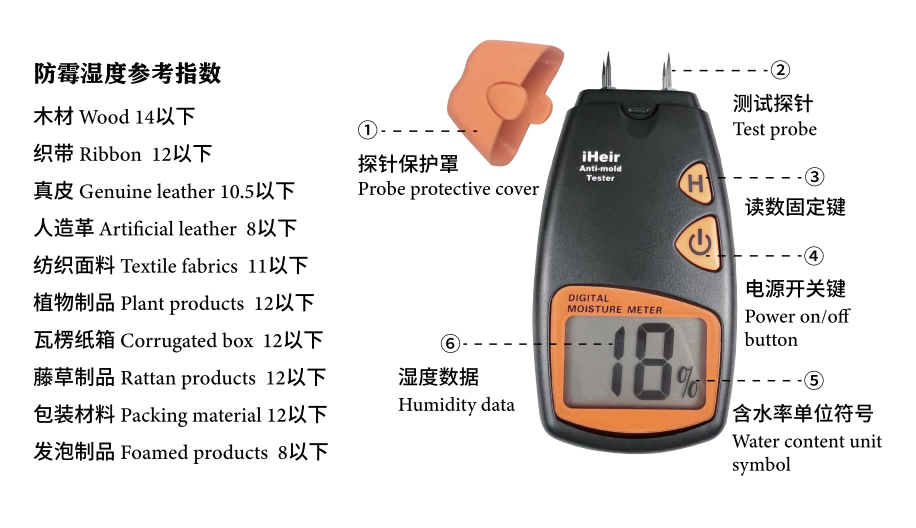

Humidity test: Pior to storage, humidity must be tested first to see if materials exceed the standard. If they exceed the standard, the supplier must rework it.

3. Warehouse environment management after storage

Humidity control: Strictly control the humidity of the warehouses (especially those located on islands) below 60 degrees, especially in warehouses on islands. Warehouse dehumidification equipment should maintain a standard level of humidity control around the clock, especially during humid weather or seasons, to prevent materials and finished products from being exposed to rain or moisture.

Door and window control: Close doors and windows from 8:00 p.m. to 8:00 a.m. Install a dual-probe thermometer and hygrometer to monitor at any time, and close doors and windows when the external humidity is higher than the internal humidity.

Warehouse layout: Strictly adhere to the princinple of keeping items away from the grounds and walls. The pallet should be positioned 10-20 cm from the ground and 50-60 cm from the wall. Materials, semi-finished products and finished products should be sealed with plastic film, maintaining a distance of 50 cm from the wall, and 60 cm from the window and doorways.

4. Regular maintenance and cleaning

Warehouse space cleaning and disinfection: It's essential to keep the floor clean and hygienic, and regularly perform antibacterial treatment on the floor. You can use a sprayer to load iHeir-Spray anti-mold and antibaterial agent (the stock solution is used here) the night before the factory is closed, and spray iHeir-Spray anti-mold and antibaterial agent on warehouse shelves, pallets, the bottom of shelves, and areas that are not easy to clean. After spraying, close the doors and windows for 24 hours. After 24 hours, open them for ventilation for half an hour in advance before personnel can enter the warehouse to work. The frequency of this disinfection work is mopping once a month in the first three months, and once every three months after three months (Note: during the rainy season, the frequency should be monthly).

Warehouse floor cleaning and disinfection: Maintain cleanliness of the floor by adding 5% iHeir-Spray anti-mold agent to the water when mopping for disinfection purposes. The disinfection frequency is once a month for the first three months and then every three months thereafter (Note: during the rainy season, the frequency should be monthly).

5. Emergency treatment

Isolation of moldy materials: Regularly inspecting the inventory, upon detecting moldy product, the inventory must be checked and isolated immediately. Isolate the moldy items to prevent contamination of other materials.

Conclusion

The mold prevention solution we provide for raw material warehouses not only serves as the foundation for ensuring smooth production, but also plays a crucial role in enhancing product quality and reducing manufacturing costs. By strictly adhering to SOP, companies can effectively reduce stockpiling, raw material wastage, and quality issues caused by improper management. With the increasingly fierce market competition, shoe factories must continuously optimize warehouse management and enhance supply chain efficiency to maintain a competitive edge. It’s our hope that through this article, businesses can better manage their warehouse resources, ensuring that every pair of shoes meets the highest standards from raw materials to finished products, thereby earning customer trust and market recognition.